Heavy Duty Cranes

“`No changes were requested, so the code remains the same. If you need any modifications, please specify!Sa KRC Cranes, ang aming mga heavy-duty crane ay dinisenyo upang hawakan ang mga matitinding karga. Nagbibigay kami ng mga heavy-duty crane para sa paggamit sa konstruksyon, pagmimina, produksyon ng bakal, at mga kapaligiran ng paggawa ng barko, at iba pa.

There are several types of heavy-duty cranes, each designed for specific applications and environments. Here are some common types:1. **Tower Crane**: Often used in construction sites for tall buildings, tower cranes have a vertical mast and a horizontal jib that can lift heavy materials to great heights.2. **Mobile Crane**: These cranes are mounted on wheeled vehicles, allowing for easy transportation and flexibility on job sites. They can be used for various lifting tasks.3. **Crawler Crane**: Equipped with tracks instead of wheels, crawler cranes are stable and can move on rough terrain. They are ideal for heavy lifting in construction and industrial applications.4. **Rough Terrain Crane**: Similar to mobile cranes but designed for off-road conditions, rough terrain cranes have large tires and a four-wheel drive system for better maneuverability.5. **All-Terrain Crane**: These cranes combine the features of mobile and rough terrain cranes, allowing them to operate on both paved and unpaved surfaces.6. **Overhead Crane**: Also known as a bridge crane, this type is used in factories and warehouses. It consists of a hoist that moves along a bridge, allowing for efficient lifting and moving of materials.7. **Gantry Crane**: Similar to overhead cranes but with a freestanding structure, gantry cranes are often used in shipping yards and for heavy lifting in outdoor environments.8. **Floating Crane**: Used in maritime applications, floating cranes are mounted on barges or ships and are capable of lifting heavy loads in water.Each type of crane has its own advantages and is suited for different lifting tasks, making it important to choose the right one for the job.

KRC Gantry Crane de alta resistencia de hasta 320 toneladas

KRC Crane de pont à usage intensif jusqu’à 600 tonnes

Sa KRC, nag-specialize kami sa engineering ng mga heavy-duty crane na dinisenyo para sa tuloy-tuloy na operasyon sa ilalim ng matinding strain. Ang aming mga crane ay kayang mag-angat ng mga karga mula sa 50 tonelada hanggang higit sa 1,000 tonelada, depende sa aplikasyon at mga espesipikasyon.

Nag-aalok kami ng mga sumusunod na uri ng heavy-duty crane:

- Gantry Cranes: Hanggang 320 tonelada

- Overhead Cranes: Hanggang 600 tonelada

Ang mga crane na ito ay itinayo upang hawakan ang mga ekstremong karga, tinitiyak ang tibay at kahusayan sa iba’t ibang industriyal na aplikasyon.

**Key Design Features of Heavy Duty Cranes**1. **Robust Structure**: Heavy duty cranes are designed with a strong and durable frame to withstand heavy loads and harsh working conditions.2. **High Load Capacity**: These cranes are engineered to lift and move extremely heavy materials, often exceeding several tons.3. **Stability and Safety**: Incorporating features like outriggers and counterweights to ensure stability during operation, minimizing the risk of tipping.4. **Advanced Control Systems**: Equipped with sophisticated control mechanisms for precise handling and maneuvering of loads.5. **Versatile Boom Configurations**: Various boom lengths and types (telescopic, lattice, etc.) to accommodate different lifting needs and site conditions.6. **Durable Materials**: Constructed from high-strength steel and other materials that can endure wear and tear over time.7. **Mobility Options**: Many heavy duty cranes are designed to be mobile, allowing them to be transported easily between job sites.8. **Maintenance Accessibility**: Designed for easy access to components for routine maintenance and repairs, ensuring longevity and reliability.9. **Safety Features**: Includes emergency stop buttons, overload protection systems, and safety alarms to enhance operator safety.10. **Environmental Considerations**: Some models are designed to operate efficiently in various environmental conditions, including extreme temperatures and weather.

Kapasitas Beban Tinggi:

Kran berat kami dirancang untuk mengangkut beban ekstrem dengan mudah dan efisiensi.Konstruksi Kokoh:

Dibangun dengan baja berkekuatan tinggi dan komponen yang diperkuat, kran ini dapat bertahan dalam kondisi keras dan lingkungan ekstrem.Kontrol Canggih:

Dilengkapi dengan sistem mutakhir seperti teknologi anti-goyang dan kontrol berbasis PLC untuk operasi yang aman dan tepat.Konfigurasi Kustom:

Kami menawarkan opsi yang dapat disesuaikan untuk memenuhi kebutuhan industri spesifik Anda, termasuk lampiran pengangkat khusus.Titik Pengangkatan Ganda:

Menampilkan sistem multi-trolley dan hoist ganda, kran ini mendistribusikan berat dengan efisien, mengurangi stres pada komponen individu.

Aplikasi Kren Berat

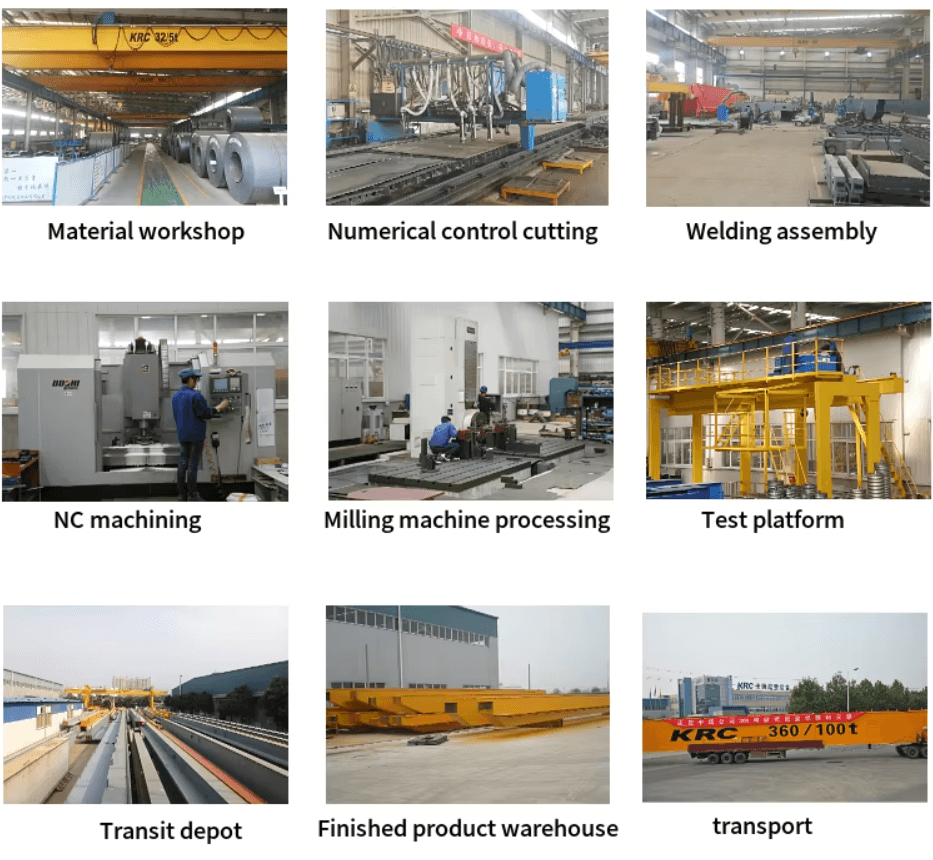

Proses Pembuatan Kren Berat

Di KRC, proses pembuatan kren berat kami melibatkan beberapa langkah kritikal untuk memastikan setiap peralatan mampu menahan beban tinggi dan tekanan persekitaran. Langkah-langkah ini termasuk:

- Reka Bentuk

- Kejuruteraan

- Pemilihan Bahan

- Pemotongan

- Pengelasan

- Pengilangan

- Pembuatan

- Pemasangan

- Ujian

- Pengawalan Kualiti

- Pemasangan

- Pengkomisenan

Kami menawarkan pelbagai pilihan kren berat untuk memenuhi keperluan khusus projek industri anda, termasuk:

- Kren 100 Tan

- Kren 150 Tan

- Kren 200 Tan

- Kren 600 Tan

¿Por qué elegir las capacidades de KDM?

Cuando inviertes en una pieza significativa de equipo como una grúa de servicio pesado, elegir un fabricante con el diseño, la ingeniería y la experiencia de fabricación adecuados es fundamental. KRC Cranes tiene más de dos décadas de experiencia líder en la industria en grúas de servicio pesado.

Utilizamos tecnología de vanguardia para crear soluciones de elevación innovadoras que están diseñadas para la excelencia operativa, la seguridad y la durabilidad.

Nuestras grúas de servicio pesado pueden operar en entornos difíciles, incluyendo condiciones climáticas extremas como altas temperaturas, bajas temperaturas y condiciones húmedas o ventosas, gracias a recubrimientos resistentes a la intemperie y componentes reforzados.

Pertanyaan yang Sering Diajukan

Bagaimana kren berat diangkut?

Oleh kerana saiznya yang besar, banyak kren berat diangkut dalam bahagian dan dipasang di lokasi untuk memastikan pemasangan dan keselamatan yang betul.

Apa kapasiti beban maksimum untuk kren berat?

Kapasiti beban maksimum berbeza bergantung pada jenis dan spesifikasi kren. Sebagai contoh, beberapa kren overhead boleh mengangkat sehingga 600 tan, manakala kren gantri boleh mengendalikan sehingga 300 tan.

Apa perbezaan antara kren 200 tan dan kren 100 tan dari segi harga?

Harga kren berat meningkat dengan kapasiti beban. Untuk harga tertentu, sila hubungi kami untuk mendapatkan sebut harga.